Solutions

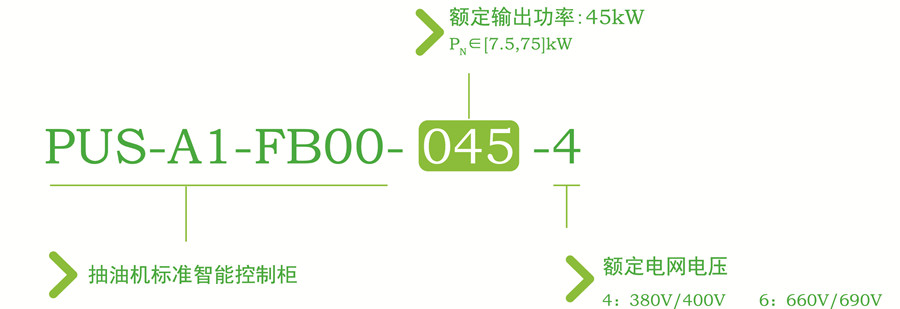

PUS pumping unit intelligent control cabinet adopts "speed sensorless vector control technology", "digital feedback technology", "DC bus voltage prediction control technology", "wireless communication technology based on SimpliciTI protocol", and saves the power of "low-yielding wells" on a large scale. Improve the crude oil output and motor power factor of "high-yield wells", realize the remote monitoring function of "attended and unattended" pumping units, prolong the service life of pumping units, reduce maintenance costs of pumping units, and improve the degree of automation of pumping unit systems .

PUS pumping unit control cabinet has many features such as high efficiency, low energy consumption, intelligence, high reliability and quick response.

The core controller of the PUS pumping unit intelligent system is designed by the Albert (Albert) Oilfield Design Institute according to the special working conditions of the oilfield pumping unit, and is produced and applied by Texas Instruments (TI). Oil fields are used extensively.

Smart/Backup Switching Function: Ensures Production Continuity

-All-round all-drive, compatible with synchronous motor and asynchronous motor control

-Cabinet protection grade: IP54, rainproof, windproof and sandproof

-LCL filtering technology: the output waveform is more perfect

Suitable for screw pump, tower crane, beam pumping machine control system application.