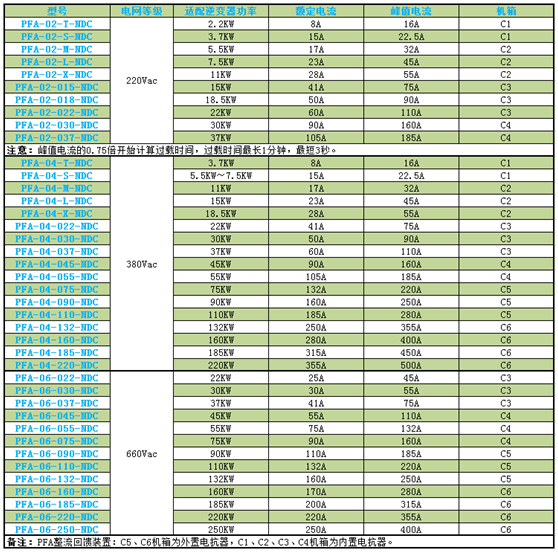

PFA rectifier feedback device

The PFA rectifier feedback device is a low-noise and high-energy-saving technology product that realizes complete sine wave current rectification and feedback. It includes reactors and noise filters, and can be directly connected to the power grid without causing damage to the power grid and surrounding electrical equipment. interference. The energy feedback efficiency is as high as 97%. Compared with general-purpose inverters, it saves 20% to 50% more energy, and the heat loss is less than 3% of the resistance braking, reducing the heat source and enhancing the safety system. The use of IGBT rectification can reduce the grid capacity by 15% to 25% compared to the use of general-purpose inverter rectifier bridge rectification.

The PFA rectifier feedback device can realize the sine wave current rectification function of high power factor, and output the DC voltage to supply power to the DC bus of the inverter, replacing the traditional diode rectification power supply method; it can also regenerative electric energy generated during the inverter speed regulation process. Feed back to the power grid to avoid the energy loss caused by the use of conventional energy-consuming braking units and achieve energy-saving effects.

⑴ Adopt high-speed DSP central processing unit:

Upgrade the new generation of rectification feedback control software, with accurate control accuracy, good stability, less harmonics, and strong anti-interference ability;

⑵ Adopt the latest SVPWM modulation technology in the industry:

Upgrade a new generation of SVPWM vector control technology to meet the current harmonic requirements of rectification feedback national standards;

⑶ Standard RS485 communication and feedback energy display:

The product is equipped with RS485 communication and keyboard communication display as standard, and all software control parameters are open for display and debugging, which is convenient for product monitoring;

⑷ To prevent the islanding effect:

The software monitors the status of the power grid in real time, and the power failure of the power grid will immediately stop the power feedback to the power grid to prevent the islanding effect;

⑸ Adopt LC filter technology:

Optimized LC filter to effectively suppress harmonics and electromagnetic interference, voltage and current THD <5%, to ensure the feedback of clean electric energy;

⑹ Adopt phase sequence automatic discrimination technology:

Upgrade the phase sequence automatic identification technology, the phase sequence of the three-phase power grid can be connected at will, and there is no need to manually distinguish the phase sequence;

⑺ The upgraded hardware design exceeds the requirements of the national standard for pressure resistance:

The newly upgraded hardware design meets the 1min withstand voltage of 2500V AC, and the leakage current is less than 2mA, which is far lower than the national standard 30mA requirement;

⑻ Improve machine rectification feedback current level:

The newly upgraded hardware and control software can reduce the volume of the product by more than 31%, and at the same time, increase the current by 34%;

⑼ Configure the fuse:

Equipped with DC and three-phase AC fuses, short-circuit protection is in place to ensure the safe operation of the inverter;

⑽ Built-in input filtering device, noise filtering in the whole process, the interference to the power grid is 1/4 of that of ordinary commercial frequency converters;

⑾ Built-in rectifier feedback active front end, which can feed regenerative electric energy back to the grid. The built-in reactor and filter can be directly connected to the power grid, and the energy feedback efficiency is as high as 97%. Compared with general-purpose inverters, it saves energy by 20% to 50%, and the heat loss is less than 3% of that of resistance braking, which reduces the heat source and enhances the safety system;

⑿ Built-in rectifier feedback active front end, using IGBT rectifier, compared with the use of general-purpose inverter rectifier bridge rectifier, can reduce the grid capacity by 15% to 25%;

⒀ Built-in rectifier feedback active front end, power factor up to 0.99;

⒁ Built-in rectifier feedback active front-end, during rated operation, the grid voltage distortion THD<5%, grid current distortion THD<5%, to meet the grid quality requirements;

⒂ All-round all-drive, compatible with permanent magnet synchronous motor and asynchronous motor controller;

⒃ 485 communication function, support 485 mainstream communication protocol in RTU mode;

⒄ It has multiple protection functions such as overcurrent, overload, short circuit, overvoltage, hardware overvoltage, undervoltage, grid phase loss, grid amplitude, overheating, external fault input, etc., to ensure that the system operates more safely and reliably;

⒅ Easy to install, debug, operate and maintain;

Name

PFA rectifier feedback device

Category

PFA rectifier feedback deviceAbout This

Please leave your details, we will contact you as soon as possible!