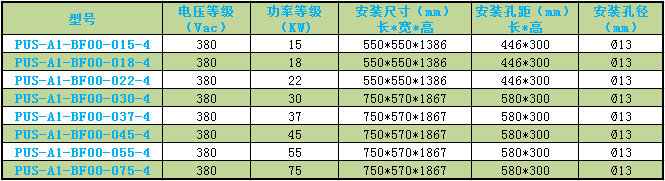

PUS pumping unit intelligent control cabinet

PUS pumping unit intelligent control cabinet energy saving and control device is an application product designed and produced according to the special working conditions of oilfield pumping units. The built-in feedback braking unit can feed the regenerative electric energy of the pumping unit back to the power grid. Through the detection of the energy-saving monitoring center of each oil field, the comprehensive power-saving rate can reach 20%~50%, and the energy-saving effect is remarkable. The pumping unit realizes the process control of soft start, soft stop and speed regulation operation, with small starting current, stable speed, reliable performance, small impact on the power grid, and can realize arbitrary adjustment of up and down stroke speed and closed-loop control operation. The user can determine the stroke, speed and liquid production of the pumping unit according to the liquid level and pressure of the oil well, which can effectively reduce energy consumption, improve pump efficiency, reduce equipment wear and prolong service life; CUP is at -40℃~+90℃ temperature can work normally under conditions. Full voltage automatic tracking, automatic calculation of the optimal braking torque, simplifying the operation of the application link.

1. Realize soft start, soft stop and speed control process control

The starting current is small, the speed is stable, the performance is reliable, and the impact on the power grid is small, and the speed of up and down strokes can be adjusted arbitrarily and closed-loop control operation.

2. The stroke, speed and liquid production of the pumping unit can be determined according to the liquid level and pressure of the oil well

Can effectively reduce energy consumption. Improve pump efficiency, reduce equipment wear and prolong service life

3. Special application program for pumping unit, simplified design, suitable for direct debugging by ordinary oil workers

4 Built-in input filter device, noise filtering throughout the whole process, the interference to the power grid is 1/4 of that of ordinary commercial frequency converters

5. Full voltage automatic tracking, automatic calculation of the best braking torque, simplifying the operation of the application link

6. Built-in regenerative braking unit, which can feed regenerative electric energy back to the grid. The built-in reactor and filter can be directly connected to the power grid, and the energy feedback efficiency is as high as 97%. Compared with general-purpose inverters, it saves 15%~25% more energy, and the heat loss is less than 3% of the resistance braking, reducing the heat source and enhancing the safety system.

7. All-round all-drive, compatible with permanent magnet synchronous motor and asynchronous motor control

8. It has a number of protection functions such as overcurrent, short circuit, overvoltage, undervoltage, phase loss, overheating, etc., to ensure safer and more reliable system operation

9. Unattended in the field, fully automatic design, the pumping speed can be controlled arbitrarily without changing mechanical equipment. Applicable to oil wells in different regions and structures, suitable for occasions with different climates and different conditions

10 Optional wireless communication module for seamless connection with oilfield digital system

Suitable for screw pump, tower crane, beam pumping machine control system application

Name

PUS pumping unit intelligent control cabinet

Category

PUS pumping unit intelligent control cabinetAbout This

Please leave your details, we will contact you as soon as possible!